Function:

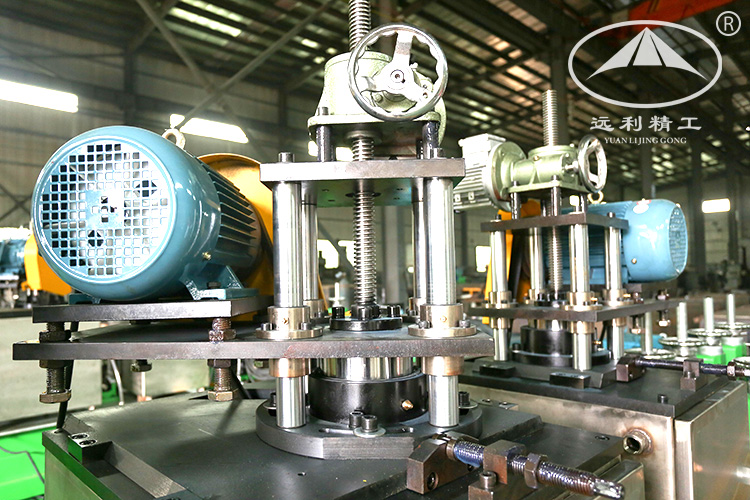

the grinding machine is used to polish the high part of the welding seam. After grinding, the welding seam is smooth and bright.The structure of the grinding machine consists of a closed SS waterproof box, grinding bearing seat, grinding main machine, elevator, reducer, motor and so on.The grinding machine is easy to operate and beautiful in shape.

Main features are:

·SS closed waterproof box body, grinding water splash;

· inverted structure, the grinding head is inverted in the box body, the transmission mechanism and adjusting mechanism are completely separated from the grinding water on the upper part of the box body, in a clean state without water and dust, not easy to rust and damage, and durable;

· grinding feed automation, realizing automatic and even feed through PLC programming and speed regulation of frequency converter;

· the grinding feed is humanized, and the device can feed automatically or manually;

· due to the even automatic feeding, the grinding quality is good, saving the consumption of materials, and reducing the labor intensity;

· easy and simple operation. The grinding head is quickly lowered by a quick button before grinding, and then converted to automatic feeding when the grinding wheel is close to the tube/pipe.

Main technical parameters:

3 grinding heads, 3KW4 grade grinding motor, 42CrMo material for grinding head shaft.Grinding head screw with M27X4 square teeth, grinding head bearing base with 4 6307 bearings, grinding head with double chrome-plated guide column sliding structure up and down, grinding box with 5mm stainless steel plate production.Thousands of impeller diameter Φ 25.4 mm

中文

中文

current location:

current location: